James Hardie siding everything you need to know

The extreme durability and sustained good look of a fiber cement siding like James Hardie make it a great choice in this part of the country. As This Old House puts it, “It masquerades as wood or masonry, wears like concrete, and survives even the harshest elements.” It is estimated that about 15% of all new homes are clad with fiber cement siding.

Given its popularity, it is hard to believe that fiber cement siding has been around for less than three decades.

What is Fiber Cement Siding?

Fiber cement siding consists primarily of silica sand or fly ash and cellulose (wood pulp). The cellulose provides resilience and flexibility, while the fly ash or silica acts as a filler. Portland cement binds it all together. During the manufacturing process, water is used to activate the cement and dissolve the wood pulp.

Today, James Hardie siding is the #1 fiber cement product in North America. It has already been installed on more than 8 million homes. Homeowners who invest in James Hardie products enjoy peace of mind that lasts for years and years.

History of James Hardie Siding

The story of today’s preeminent fiber cement siding began in the 19th century. As a young man, James Hardie left his family’s Scottish tannery business to emigrate to Australia in 1888. He decided to strike out on his own, determined to build his own import business. Andrew Reid, an acquaintance of Hardie’s in Scotland, emigrated to Australia in 1892. By 1895, he was a full partner in James Hardie’s growing enterprise. When he retired in 1911, Hardie sold his half of the business to Reid. Three generations of the Reid family would operate the business until 1995. James Hardie Industries LLC is now a public company whose stock is traded on the New York Consolidated Stock Exchange.

Today, James Hardie siding and other building products are sold on four continents – North America, Europe, Asia, and Australia. Focusing purely on fiber cement products, James Hardie has international revenues of more than $1.5 billion, and it employs more than 2,500 people.

James Hardie Siding Options

You want to make sure that your siding selection complements your home in every way possible. The success of James Hardie Industries enables it to manufacture a wide variety of siding styles, making this brand of fiber cement siding compatible with an exceedingly wide range of architectural styles.

HardiePlank – Traditional and timeless. Sleek and strong. HardiePlank lap siding is the best-selling product from James Hardie. In fact, it is now the most popular type of residential siding in all of North America. HardiePlank siding offers a timeless, traditional look that works well with many different architectural designs. You can select from four profiles: Select Cedarmill, Smooth, Beaded Cedarmill, and Beaded Smooth. The standard 5/16-inch thick HardiePlank board is 8.25 inches wide and 144 inches long.

HardieShingle – Due to its enhanced cedar shingle look, the Hardieshingle product is an ideal choice for Cape Cod residences. It also adds character to many other architectural styles as well. Choose from staggered edge panel and straight edge panel designs. The 48-inch panels are 0.25-inch thick. 15.25-inch wide panels provide a 7-inch exposure, while the 14-inch wide panels provide a 5-inch exposure.

HardiePanel – The clean, crisp lines of HardiePanel vertical siding make a statement without getting too trendy. Some homeowners combine it with HardiePlank lap siding to really make a statement. Select from four profiles: Select Cedarmill, Smooth, Stucco or Sierra 8. The 5/16-inch thick panels are available in 4×8, 4×9, and 4×10 sizes (dimensions in feet).

Artisan – The Artisan Collection from James Hardie is at once tasteful, textured and tantalizing. The extra-thick lap siding allows for deep shadow lines, providing a compelling 3-dimensional look. Artisan siding represents the perfect marriage of an authentic cedar profile and super-durable fiber cement construction. Artisan siding comes in 144-inch lengths that are ⅝-inch thick. There are 5.25, 7.25 and 8.25-inch widths that provide 4.0, 6.0 and 7.0 inches of exposure, respectively.

Accessories – James Hardie Industries also manufactures complementary trim, soffits, flashing and house wrap so your project can feature high-quality products throughout.

ColorPlus technology – Although it is possible to install primed siding and have it painted on-site, James Hardie’s exclusive ColorPlus technology offers real advantages. It features:

- Multiple coats of a proprietary finish formulated to resist UV fading.

- A finish is applied to every surface of every piece of siding.

- Controlled curing between coats enhances chip, peel, and crack resistance.

The factory-applied, fully cured ColorPlus finish includes more coats than a typical house painter applies on-site. Ultimately, James Hardie’s exclusive ColorPlus technology results in siding that looks great for years and years.

Advantages of James Hardie Siding

For years, when homeowners thought about siding, the word “vinyl” quickly came to mind. Now, many are realizing the significant benefits of rugged fiber cement siding like James Hardie.

Consider the many advantages of James Hardie siding over vinyl. It’s highly resistant to:

- Fading

- Cracking

- Fire and heat

- Warping

Other advantages include the fact that it:

- Is greener and more sustainable

- Is thicker and more resistant to damage

- Is more receptive to stylish deep embossing

- Includes lengthy manufacturer warranties

- Requires minimal maintenance

- Offers better return on investment (ROI)

When you invest in James Hardie siding, you may find that it could increase your home’s value. In fact, Remodeling magazine calculates an average 78 percent ROI at the time of resale.

James Hardie siding comes with a solid 30-year manufacturer’s limited warranty. Since this warranty is transferable, it can be used as a selling point should you put your home on the market at some point.

For those living close to the coast, it is worth noting that James Hardie products stand up to both salt air and high humidity. And, when the hot sun of summer arrives, the ColorPlus finish on select James Hardie products is superbly UV-resistant. At the same time, it stays flexible and resilient when those inevitable arctic blasts descend from Canada.

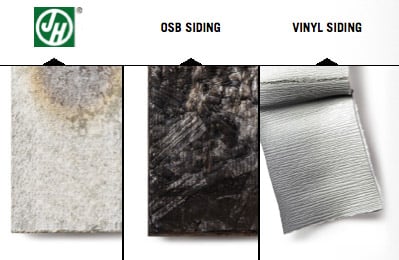

James Hardie Siding vs. Vinyl Siding

How does James Hardie siding compare to traditional vinyl? Quite favorably, for a number of important reasons:

- Aesthetics – Vinyl siding is a plastic product, and there is no way for it to successfully emulate the look and feel of wood. Also, deep embossing is not possible because it is so thin. Curb appeal is compromised by the visible overlaps from one section to another.

- Chemical content – So-called “vinyl” siding is typically produced from a plastic resin, polyvinyl chloride (PVC). In the unfortunate event of a house fire, burning PVC can release a number of toxins, including hydrogen chloride gas and dioxin. By comparison, fiber cement is not flammable, and its component materials, cellulose and fly ash (or silica), are quite benign, particularly when they are bound together by Portland cement.

- Sustainability – Vinyl siding is not considered a sustainable product. Production of PVC resin is not environmentally friendly – it produces approximately double the carbon emissions during fiber cement production. The toxins produced as vinyl is produced is an even greater concern. Although recycling vinyl siding is possible, logistical issues mean that most of it still ends up in landfills.

- Cracking – Even when vinyl siding is properly installed, impacts during cold snaps may cause it to crack. Holes may even appear. Undetected cracks can allow moisture to infiltrate the exterior wall, potentially leading to wood rot or mold growth.

- Warping/buckling – Vinyl siding is subject to significant expansion and contraction. With our annual temperature swings of 90-100 degrees or more, this is a real concern. For example, a 12-foot section of vinyl siding can expand and contract as much as five-eighths of an inch. As a result, nails need to be positioned in the center of the nailing slots to allow each panel to freely expand and contract.

- Even experienced installers may err when nailing the vinyl siding to the house. The problem with improper nailing is that you don’t know you have a problem until warping or even buckling appears.

- Moisture retention – Warping and buckling are not only unsightly, but they may also open up gaps that allow for excess moisture intrusion, particularly in heavy wind-blown rains. When vinyl siding is installed with an insulation foam backing to add R-value, problems with trapped moisture are also possible. Moisture behind vinyl siding can lead to rotting, mold, or mildew.

- Temperature sensitivity – Vinyl siding is far thinner and more temperature sensitive than James Hardie siding. Consequently, if you get your grill too close, the vinyl siding may warp.

- Wind vulnerability – High winds in tropical systems, severe thunderstorms, and howling blizzards can get under vinyl siding, potentially ripping it from a home. By contrast, properly installed James Hardie siding can withstand the kind of hurricane-force winds the DMV occasionally experiences.

- Cost – Although homeowners are initially attracted to vinyl siding by the lower materials expense, upfront costs are only part of the equation because total life cycle costs matter too. For example, consider that James Hardie siding can easily last two decades longer than its vinyl counterpart. Higher maintenance and repair costs associated with vinyl may more than erase any upfront savings.

Importance of Proper Installation

Proper installation is the key to optimizing the performance of James Hardie siding. The manufacturer recommends that “The best way to get the performance you expect from your James Hardie products is to work with a professional contractor.”

James Hardie Industries works with installation specialists that focus on important things like safety, onsite training, and education. These specialists know how to maximize the performance of siding, trim, soffit, flashing, and wrap products through installation best practices. For example, certified James Hardie specialists know how to meet OSHA silica dust standards during installation.

When pre-finished ColorPlus siding is installed, it is essential that all freshly cut, open edges be caulked and sealed to prevent moisture intrusion. An inexperienced contractor may fail to do this. Due to its cement content, James Hardie siding requires the proper use of fasteners to maximize its wind resistance.

James Hardie siding is a low-maintenance product. It’s ideal to occasionally spray it with a garden hose or a pressure washer to wash away dust, dirt, cobwebs, and other accumulated debris. Although it is not necessary every year, caulked joints should be inspected periodically and restored, if necessary. Finally, since it is ideal to keep shrubbery from rubbing up against your siding, timely pruning is recommended.

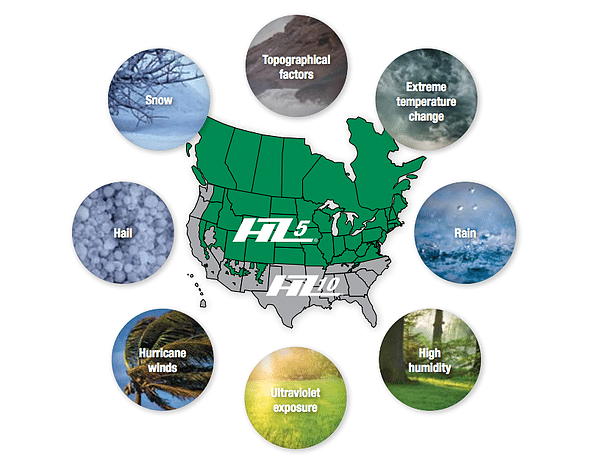

HardieZone System

The manufacturer engineers two types of James Hardie siding to accommodate the ten primary climate zones in the United States. The two types are referred to as HardieZone 5 (HZ5) and HardieZone 10 (HZ10). Maryland, Virginia, and Washington, DC, are in the southern part of the region designated for HZ5 siding.

HZ5 James Hardie siding is specifically engineered to retain dimensional stability despite seasonal weather extremes. Advanced paint adhesion and moisture resistance resist everything from severe thunderstorms to howling blizzards. The HZ5 design also includes a drip edge to enhance water management. HZ5 siding comes with a 30-year limited, transferable warranty that adds value if and when you decide to sell your home. It is vital to install HZ5 siding in our region, as the use of HZ10 siding here voids the manufacturer’s warranty.

By comparison, HZ10 siding is specially engineered for added moisture protection in tropical climates. It is engineered more for protection from hurricane-force winds and heavy rain and less for protection from arctic blasts, heavy snow, and ice. It also comes with a 30-year limited, transferable warranty provided by the manufacturer.

Finally, the HardieZone system considers both geographic locations as well as elevation. This means that if you have a cousin living in the Georgia mountains above 2,000 feet, HZ5 would still be the recommended siding.

About BRAX

BRAX Roofing is a certified James Hardie installer serving Northern Virginia, Maryland, and Washington, DC. We are a full-service siding contractor committed to meeting all of our client’s needs, from minor repairs to complete re-siding. We also offer comprehensive roofing services as well as window and door replacements.

Are you ready to arrange for the highest quality home improvements at a reasonable cost? For prompt, professional, and friendly assistance, please contact us today for a free estimate!

Contact Us for a Free Estimate

What to Expect When

You Choose Our Team

We’re Committed to You

Every Step of the Way

- Meet to discuss your project and free estimate.

- Select materials and colors for the look you want.

- Arrange payment through financing or your insurance.

- Install new roofing, siding, or gutters for amazing results.

- Ensure you’re 100% satisfied with our services.