All About Cedar Shake Roofing

The two tree species most commonly used for cedar shakes are Western Red Cedar and Alaskan Yellow Cedar.

Western Red Cedar (Thuja plicata) is native to western North America, with some of the greatest concentrations found in Washington state and the Canadian province of British Columbia. It favored for shakes for a number of reasons:

- Strong yet lightweight

- High resistance to decay

- Attractive red-brown appearance

- Tight grain and relatively few knots

Western red cedar is crafted into many finished products, including utensils, instruments, and canoes. Mature red cedars can grow to heights of 125 feet or more.

Alaska Yellow Cedar (Cupressus nootkatensis) is native to the coastal areas of northwestern North America, from Alaska’s Kenai Peninsula to California’s Klamath Mountains. It grows well in cool, wet areas, often near the tree line. Relatively slow growth yields a tight grain pattern that adds to its hardness and strength. It is also splinter-resistant, insect-resistant, and even acid-resistant. Seasoned yellow cedar is almost scent-free. Its inherent beauty and straight grain make it popular for use in refined products like bows, saunas, boats, and canoe paddles.

Color preferences, particularly when the shakes will be part of historic preservation, often guide the selection of one cedar species over another.

History of Cedar in Construction

Cedar’s durability has made it a popular construction material for centuries. 5,000-year-old tools made from red cedar have been discovered in British Columbia. The “Cedars of Lebanon” were used to construct the Temple of Solomon almost three thousand years ago. In many parts of America, roofs covered with wood were the norm until a century ago when asphalt shingles made their debut. Today, those with historic homes often choose cedar shakes for their authenticity, beauty, and durability.

Cedar Shake and Shingle Bureau

The Cedar Shake and Shingle Bureau (CSSB) is a nonprofit organization responsible for the certified inspection of shakes made from Alaska Yellow Cedar, Western Red Cedar, and Redwood (Sequoia sempervirens). CSSB member mills are required to adhere to established quality standards. Compliance is ensured through third-party inspections.

The following terms signify that bundles of cedar shakes meet various grading and performance standards:

- Certi-Split

- Certi-Sawn

- Certi-Guard

- Certi-Last

Cedar shakes are also graded according to a variety of standards related to impact, wind, and fire resistance. Every bundle of shakes includes a color-coded label that states the grade, the species, certifying party, building code standards, and the manufacturer.

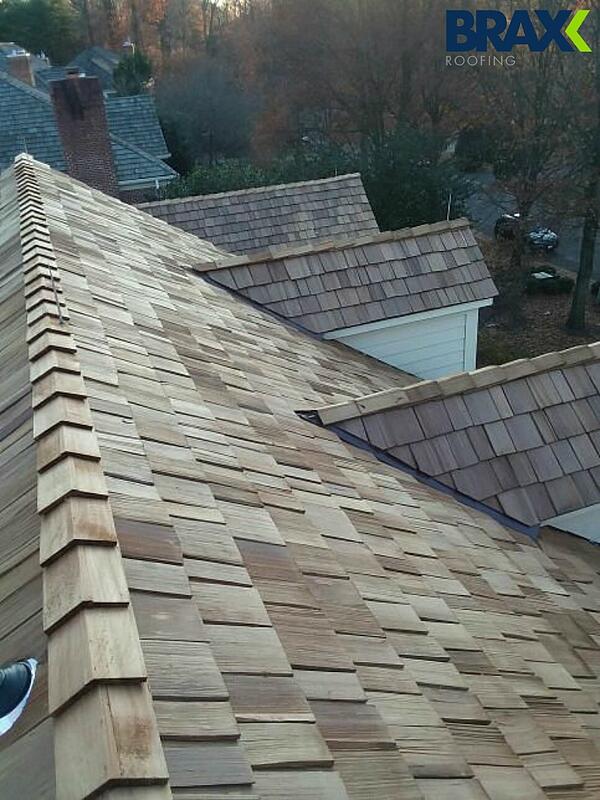

Types of Cedar Shake Roofing

You will more easily understand the different designations if you first visualize a tree’s growth rings. Edge grain shakes are cut or split perpendicular to the rings, while flat grain shakes are cut or split at less than a 45-degree angle to the rings. Finally, slash grain shakes are cut at more than a 45-degree angle to the rings.

Edge Grain

Edge grain shakes come from cedar cut perpendicular to a tree’s growth rings. They possess a tight grain that makes them extremely stable. Edge grain shakes are known by various names, including quarter-sawn, vertical grain, radial grain, and rift sawn. This type of shake is less vulnerable to distortions caused by changes in moisture content. Premium shakes must be all edge-grain. #1 shakes must be mostly edge-grain, with up to 20% flat-grain.

Flat Grain

The grain of these shakes runs more parallel to their long dimension. The problem with flat-grain shakes is that they are prone to splitting along the centerline. They also tend to absorb moisture, which can lead to cupping, curling, and other problems.

Slash Grain

Slash-grain shakes have a wavy grain resulting from cutting more than 45 degrees from vertical. Slash-grain shakes are also relatively unstable. Natural weathering may lead to various kinds of deterioration, including splitting, checking, distortion and erosion.

High grades, like Premium and #1, demonstrate dimensional stability that makes them resistant to splitting, twisting, curling, cracking, and cupping. They are also resistant to erosion and wear, making them a long-lasting roofing option.

Also, there are four primary kinds of cuts used in creating cedar shakes: taper-split, taper-sawn, straight-split, and hand-split. Aesthetics often guide a homeowner to select one style over another. Some homeowners will prefer the more three-dimensional split look, while others will prefer the smoother look of sawn shakes.

Understanding Grading

The CSSB, a respected authority in the business, oversees the grading of cedar shakes produced by member mills. The International Residential Code (IRC) commonly refers to cedar shake standards established by the CSSB. CSSB-authorized labels distinguish between Premium and #1-grade cedar shakes. The label also identifies independent 3rd-party certification.

Certi-Split

Certi-Split shakes feature a split face and a sawn back. They are usually 18 or 24 inches long with a butt thickness ranging from ⅜-inch to 1-inch. However, so-called jumbo shakes have a butt thickness of at least one inch.

Certi-Sawn

Certi-Sawn taper-sawn shakes are sawn on both sides. The semi-textured face still offers a pleasing shadow line. This type of shake is also 18 or 24 inches long, although thicknesses range from ⅝-inch to 1.5 inches.

Performance Ratings

Since performance ratings cannot be confirmed through simple visual inspection, documentation by an accredited authority like the CSSB is important. All types of roof materials undergo the same rigorous testing for wind, impact and fire resistance.

Wind resistance

UL 1897 evaluates resistance to wind uplift. In the most recent testing of CSSB-member shakes installed using ring-shank nails, Underwriter Laboratories rated them at 190 mph. Subsequent testing by Exterior Research and Design yielded a 245-mph rating. Certi-label shakes also meet the standards set forth in TAS 100-95 Uplift Testing, required by Miami-Dade County’s tough wind-resistance codes. Labels on bundles of cedar shakes note compliance with standards such as UL 1897 or TAS 100-95.

Fire resistance

It is possible to treat cedar shakes to make them fire-resistant. There are three fire ratings for treated cedar shakes: Class A, B, and C. A Class A fire rating requires the installation of Class B fire-rated cedar shakes over an asphalt cap sheet. Since treatment companies provide warranties, it is important that you use a certified installer so that their warranty requirements are met. Untreated cedar shakes are not fire-rated at all.

Fire resistance testing establishes how long a roof system can resist fire penetration. You’ll find Class A, Class B, Class C, and unrated. Fire ratings are the same for all roof systems, including cedar shakes, asphalt shingles, tile, metal, and other materials.

UL 790 specifies testing protocols for achieving a Class A, B or C fire rating:

- Intermittent flame

- Spreading of flame

- Burning brand

- Flying brand

Local codes often specify the use of Class A roofing systems in areas prone to wildfires, while a Class B rating is often required on multi-family residential and commercial structures. Certi-label cedar shakes are available that meet either Class A, B, or C requirements.

Impact Resistance

“Class 3” and “Class 4” refer to levels of impact resistance. Class 4 shakes offer the greatest impact resistance. CSSB-member Certi-label shakes are typically rated for impact resistance. UL’s 2218 test standard involves dropping steel balls two inches in diameter from a height of 20 feet. All Class 4 roofs demonstrate the same impact resistance whether they consist of cedar shakes, asphalt shingles, metal, or other materials. Cedar shakes meeting standard 2218 will be labeled accordingly. If a large hailstone does ever split a shake, it can be replaced without replacing adjoining shakes that survived the hail. Natural weathering will bring about a color match.

Treated Cedar Shakes

It is important to distinguish between pressure-treated and preservative-treated cedar shakes. Certi-Guard shakes are pressure-treated in a way that makes them fire-retardant. Building codes across the country often refer to this type of treated cedar shake.

On the other hand, Certi-Last shakes are impregnated with preservatives under pressure to address fungal decay and moss growth. They are produced in accordance with standards set forth by the American Wood Preservers Association.

When it comes to treated shakes, certifications are very important because a mere visual inspection cannot confirm the presence of either treatment. Fortunately, bundles of treated, CSSB-certified shakes come with a label providing information about shakes pressure-treated with a fire retardant or a preservative that resists fungal decay.

You’ll only find pressure-treated shakes among Premium and #1 Grade shakes.

Installation of Cedar Shake Roofing

Certified cedar shake installers understand the importance of giving bundles of cedar shakes time to acclimate to local weather conditions. Such installers also understand the need to use the proper fasteners and space them correctly. They also understand the need for correct spacing, proper ventilation, and appropriate sheathing. In areas with wind-driven snow, including the DMV, solid sheathing is important to limit moisture intrusion. The use of solid sheathing is also important in under-treated cedar shakes. Certi-label shakes have been tested with plywood sheathing, although OSB can be an appropriate alternative.

By contrast, improper installation may lead to a number of problems. The use of smooth shank nails can make the roof more subject to damage from wind uplift. Non-uniform nailing is another common problem that compromises wind resistance. Improper use of a nail gun can split or otherwise weaken shakes as they are installed. Poor placement of shakes and poor ventilation may cause premature deterioration. Also, cedar shake roofs must be engineered and installed to maximize drainage. Standing water or excess moisture will accelerate the deterioration of the shakes.

Maintenance & Repair of Cedar Shake Roofing

Cedar shake roofs typically require only minimal maintenance over the years. If an individual shake happens to split, fall off or come loose at some point, it can be easily replaced – there is no need to re-do a whole section of the roof. However, repairs should be completed by an experienced contractor. A proper, professional repair ensures that the integrity of the roof remains so future leaks are avoided.

Periodic roof inspections will detect the occasional problem shake. Also, if you have large trees on your property, it is important to cut back encroaching branches from time to time, so they don’t continually rub against the roof. Over time, cedar shakes turn gray as they gracefully age. However, if some discoloration appears, it is wise to use the weakest cleaner possible. Avoid excessive power washing because it can actually lead to a loss of fiber in the cedar shakes.

Cedar Shake Roofing Warranties

Homeowners that work with a CSSB-certified installer enjoy added peace of mind and warranties they can count on. This is because the CSSB administers manufacturer’s lifetime limited warranties on behalf of their member mills when Certi-label shakes are installed by approved installers.

Homeowners who select pressure-treated shakes should understand that the treatment company also warranties their work. Your installer can inform you of the terms of this additional warranty protection.

A roofing contractor must also take full responsibility for workmanship. The roofing company must install cedar shakes to code and

to all other applicable standards.

Cedar Shake Roofing and Sustainability

Certi-label cedar shakes are highly sustainable, green products. CSSB members commit to selling “Forest Certified Products” produced from salvaged trees/logs that would otherwise remain on the forest floor. This practice contributes to maintaining the health of North America’s forests. Since standing cedar trees are not harvested to produce cedar shakes, they are considered highly sustainable products.

Compare cedar shakes to other roofing materials that are not as green, like vinyl siding, which is fabricated from ethylene and chlorine. Ethylene is derived from naphtha, which comes from crude oil. Nitrogen oxide and dioxin are released during the manufacture of vinyl siding, although this issue is somewhat minimized when the siding is fabricated from recycled vinyl.

Why BRAX Roofing

BRAX Roofing provides the superior products and expert craftsmanship that homeowners in Maryland, Washington D.C., and Virginia value. BRAX is a true full-service roofing contractor offering routine roof inspections, minor repairs, emergency work, and full roof replacements.

We’d welcome the opportunity to inspect and evaluate your roofing system so we can make recommendations that will help you make educated decisions now and in the future.

Please contact us today to schedule your complimentary roof inspection!

Contact Us for a Free Estimate

What to Expect When

You Choose Our Team

We’re Committed to You

Every Step of the Way

- Meet to discuss your project and free estimate.

- Select materials and colors for the look you want.

- Arrange payment through financing or your insurance.

- Install new roofing, siding, or gutters for amazing results.

- Ensure you’re 100% satisfied with our services.